10-10 is an full automatic block making machine line, It is composed of crusher, soil screen machine , pan mixer, conveyor belt, brick making machine, brick conveyor machine, pallet feeder, stacker, You can choose suitable supporting facilities according to your requirements.

| Dimention | 2400*2100*2200mm |

|---|---|

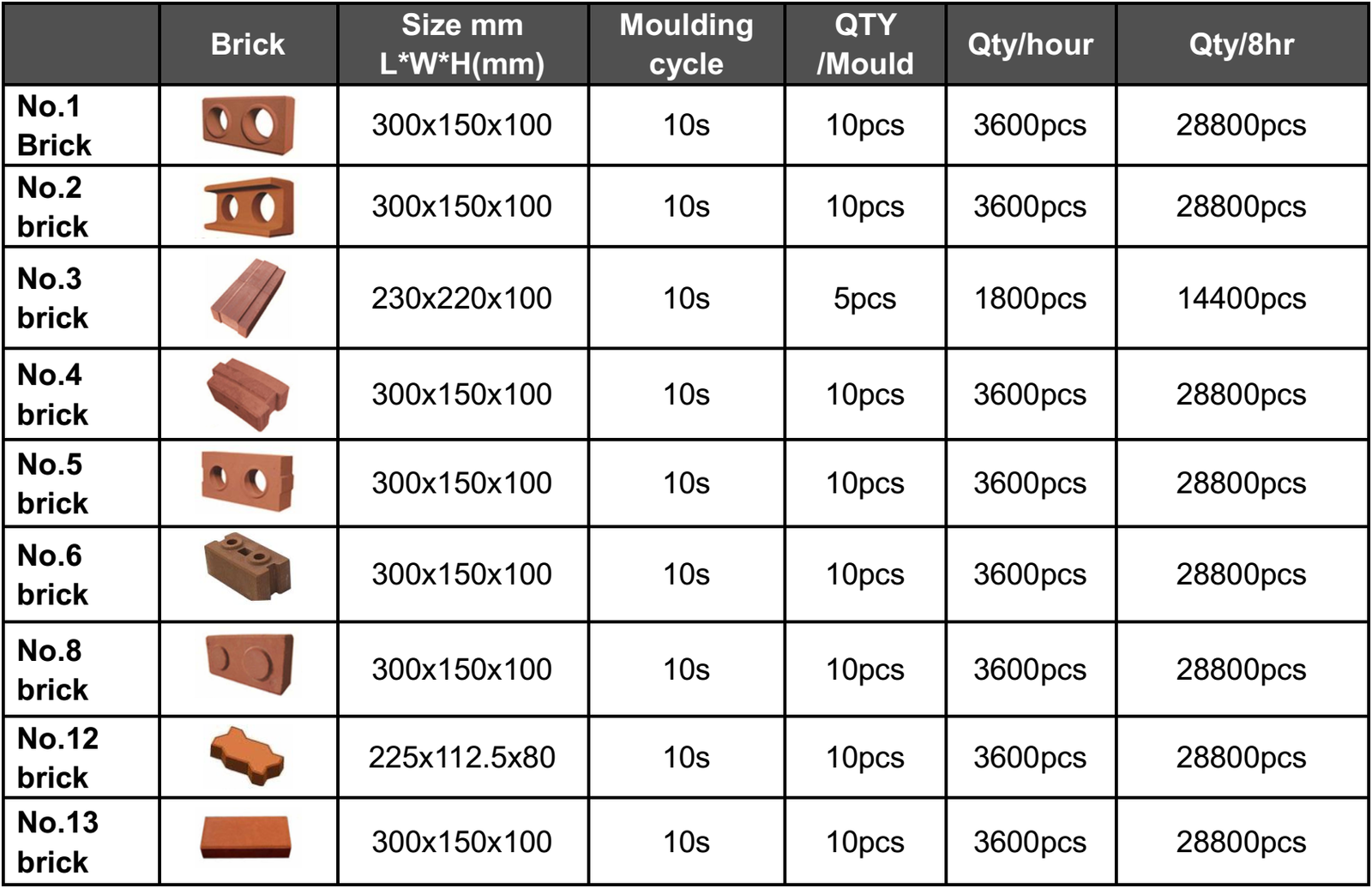

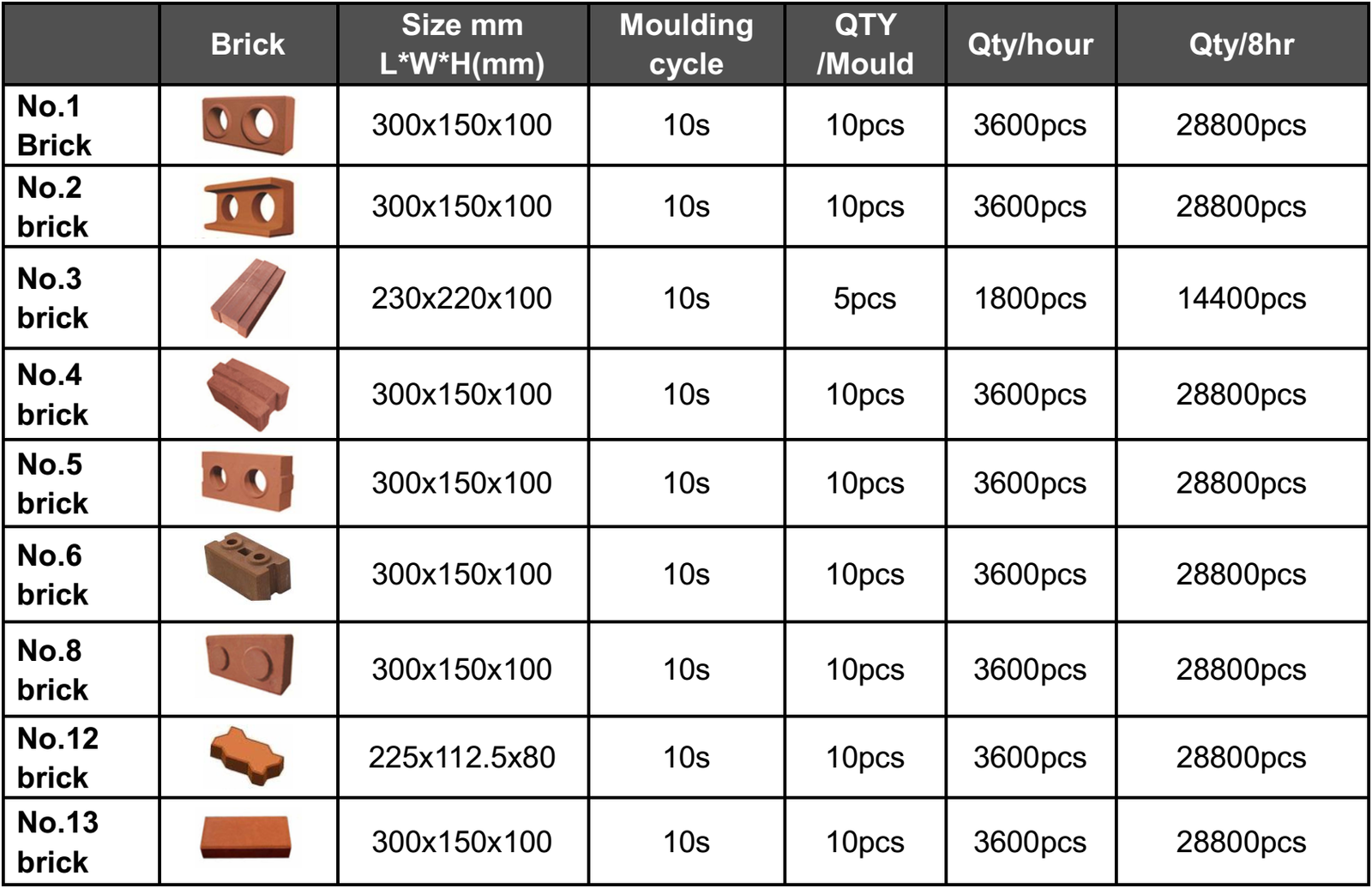

| capacity | 28800Pcs/8 hours |

| Pieces/Mould | 10 pcs/mould |

| Shaping cycle | 8-10s |

| Power | 18.5 KW |

| Voltage | Adjustable |

10-10 is an full automatic soil Interlocking brick making machine line, It is composed of crusher, soil screen machine , pan mixer, conveyor belt, brick making machine, brick conveyor machine, pallet feeder, stacker, You can choose suitable supporting facilities according to your requirements.

Making 10 bricks at one time, and shaping cycle only 8~10 seconds, so the daily capacity as high as 28800 pieces.

All mould use precise wire cutting and carburizing heat treatment to prolong its service life.The machine frame is made of special thick steel and using special welding techniques. The whole machine is strong and durable.

Hydraulic pressure technology is adopted by this machine, so the blocks produced are of good quality, large density and high strength.

Main Parameter:

| Dimension | 2400*2100*2200mm | Weight | 1900Kg |

| Shaping cycle | 8-10s | Pressure | 31.5 Mpa |

| Host machine power | 18.5 KW | Pieces/Mould | 10 |

| Capacity | 28800Pcs/8 hours | Voltage | Adopts to local voltage |

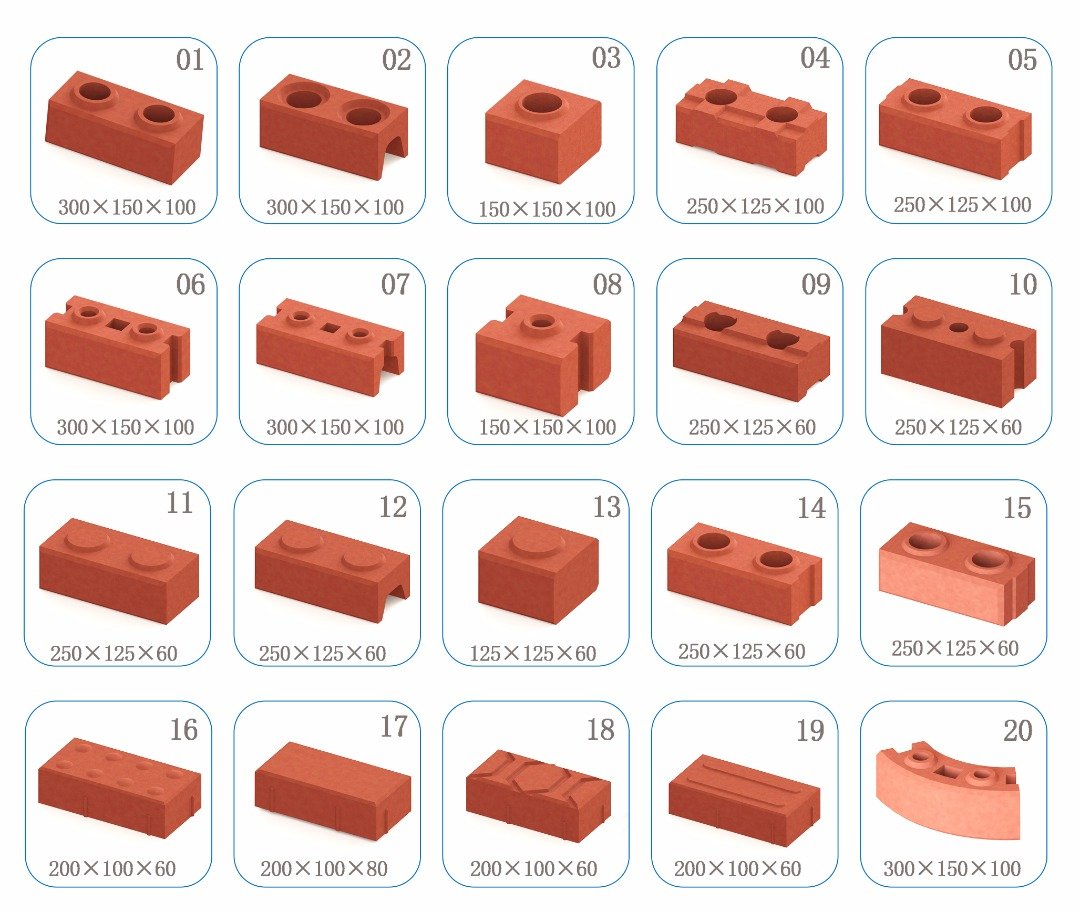

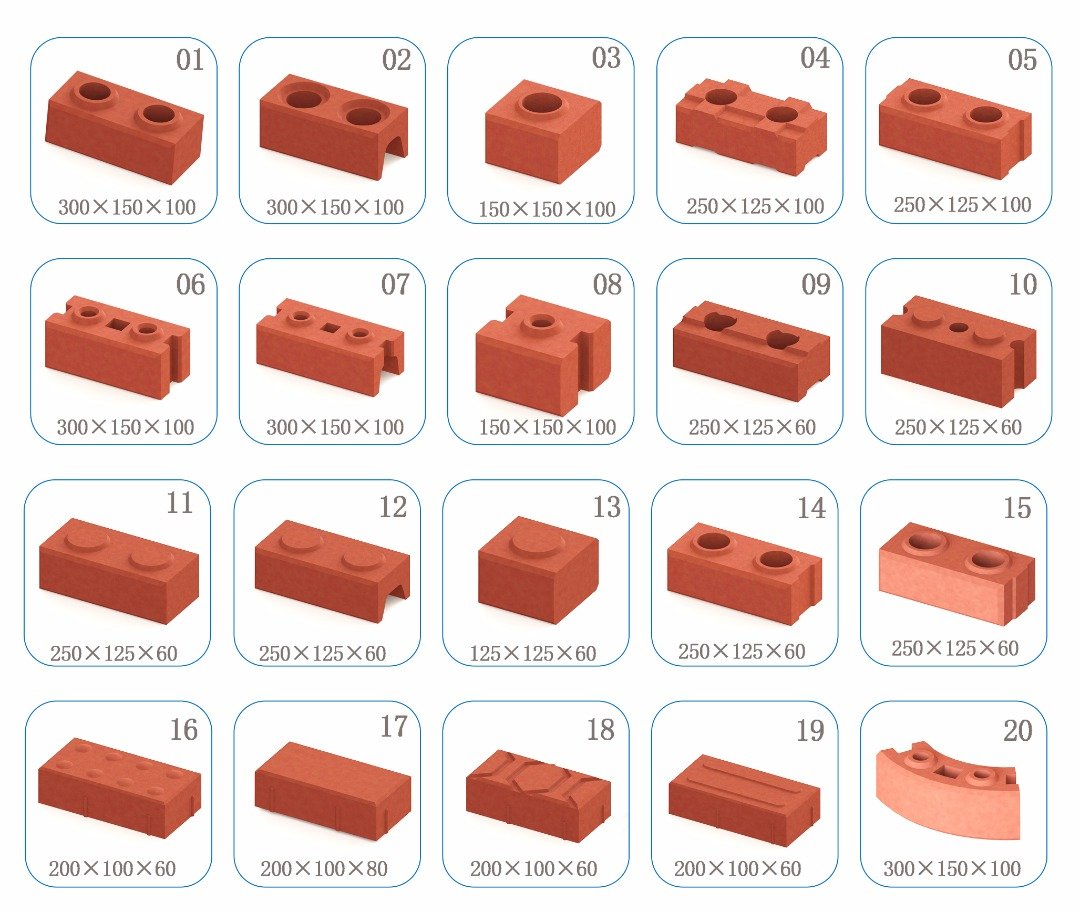

Interlocking Blocks Samples :

Notice :

1. All 10-10 automatic soil interlocking brick making machine need to load into a 20GP container.

2. 10-10 automatic soil interlocking brick making machine mold changeable

3. Total need 4 workers. 1 for crusher, 1 for screen and mixer, 2 for block delivery

4. Raw material proportion for your reference:

a. Clay: 100% clay

b. 10% cement, 90% stone powder

c. 10% cement, 30% fly ash, 60% stone powder

d. 10%-25% cement, 75%-90% clay

WhatsApp us

We will contact you within 24 hours, please pay attention to the email with the suffix “Darren@iblockmachine.com”.