5-10 is an full automatic interlocking block making machine line. It is composed of crusher, sieve, pan mixer, conveyor belt and brick making machine. You can choose suitable supporting facilities according to your requirements.

| Dimention | 1900x1515x2210mm |

|---|---|

| capacity | 14400Pcs/8 hours |

| Pieces/Mould | 5 pcs/mould |

| Shaping cycle | 8-10s |

| Power | 11 KW |

| Voltage | Adjustable |

5-10 is an full automatic interlocking block making machine line. It is composed of crusher, sieve, pan mixer, conveyor belt and brick making machine. You can choose suitable supporting facilities according to your requirements.

Hydraulic system is adopted by this machine, and it can make the bricks produced more durable and stronger.

5-10 paver block making machine can produce 5 pieces bricks one mould, its production capacity can reach 14400 Pcs per 8 hours.

Best steel Q345D and special welding techniques (CO2 gas protective welding ) make the machine strong and of high resistance to vibration.

Double oil cylinder makes the brick much strong.

Main Parameter :

| Dimension | 1900x1515x2210mm | Weight | 1500Kg |

| Shaping cycle | 8-10s | Pressure | 60Mpa |

| Host machine power | 11 KW | Pieces/Mould | 5 |

| Capacity | 14400Pcs/8 hours | Voltage | Adopts to local voltage |

5-10 Clay block factory all items investment information solution:

| Total Line Power Consumption | 32.85 kw/h; 262.8 kw/8 hours |

| Max. Material Consumption Per 8 Hours a. 10% cement, 90% clay b. 250-125-75MM; 2 holes hollow block | Water: about 1152 kgs |

| Cement: about 5645 kgs | |

| Clay: about 50803 kgs | |

| Factory total size | At least 1000 square meters |

| Workers | 4-5 workers in factory |

| Main parts quality | Motor: Shanbo brand (Chinese famous brand) PLC: Vigor from Taiwan Inductor and Switch: CHNT and Schnelder |

| Warranty | One year |

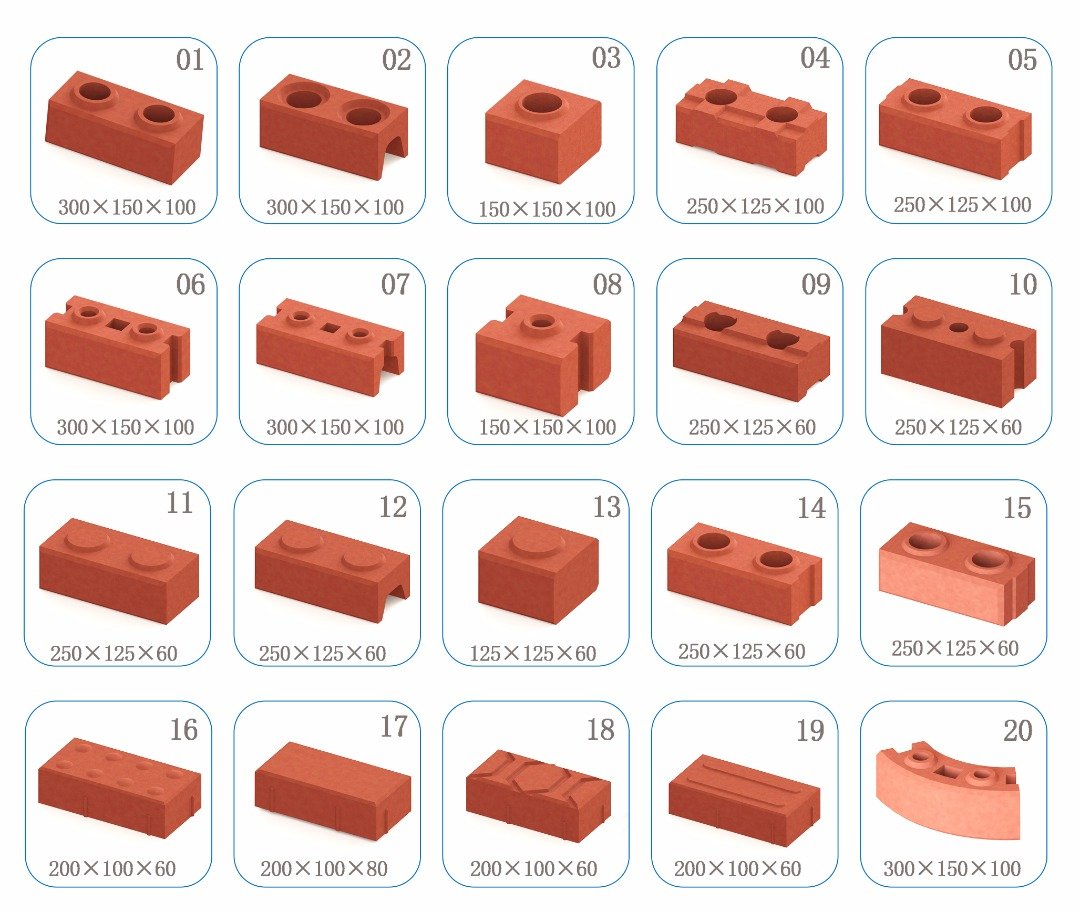

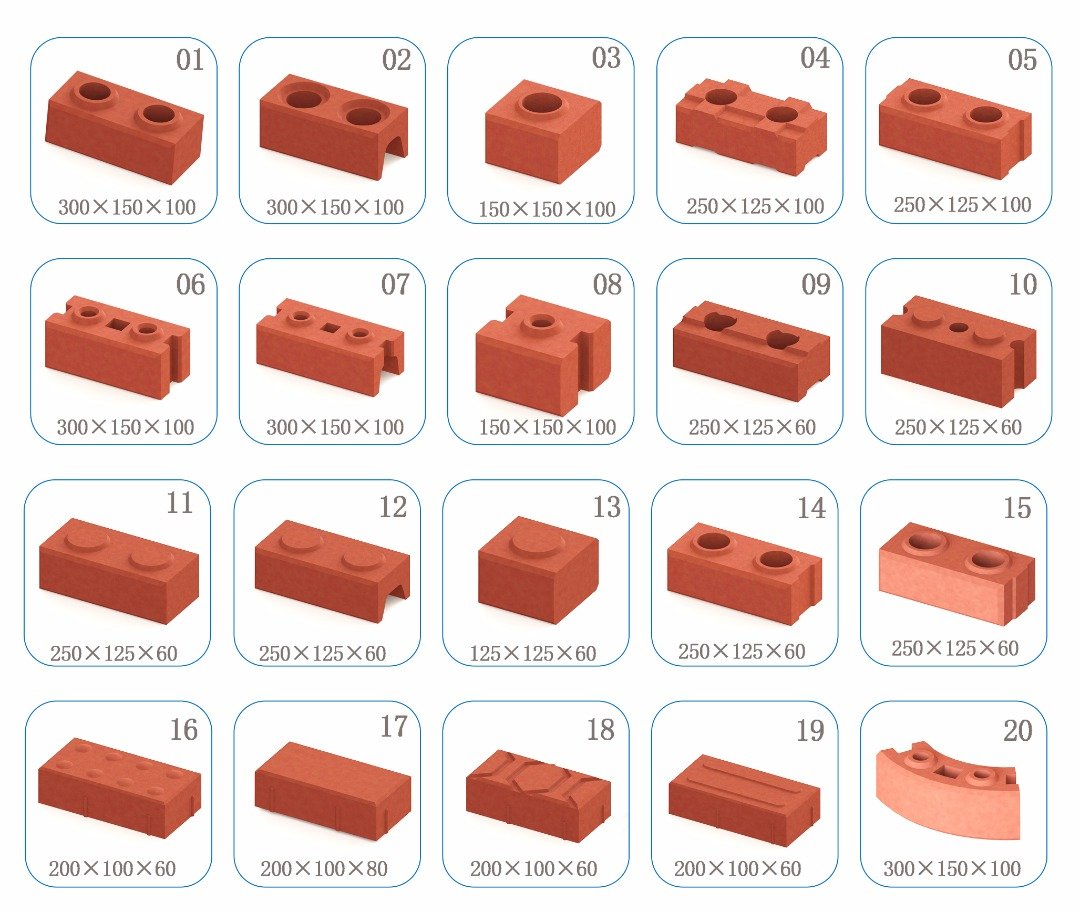

Interlocking Blocks Samples :

Notice :

1. All 5-10 block machines need to load into a 20GP container.

2. 5-10 machine mold changeable

3. Total need 4 workers. 1 for crusher, 1 for screen and mixer, 2 for block delivery

4. Raw material proportion for your reference:

a. Clay: 100% clay

b. 10% cement, 90% stone powder

c. 10% cement, 30% fly ash, 60% stone powder

d. 10%-25% cement, 75%-90% clay

WhatsApp us

We will contact you within 24 hours, please pay attention to the email with the suffix “Darren@iblockmachine.com”.