QT8-15 is an automatic hydraulic concrete block making machine production line.The blocks making machine can produce different kinds of concrete blocks, pavers, interlocking bricks, curbstones by exchanging mould. Raw material is cement, stone, sand, flyash, slag, cinder, perlite and other industrial waste.

| Dimention | 5300*2250*2700mm |

|---|---|

| capacity | 30000-120000pcs/day |

| Pallet Size | 900x800x25mm |

| Power | 49.2kw |

| Shaping cycle | 15~20s |

| Voltage | Adjustable |

| Weight | 8.5ton |

Machine introduction

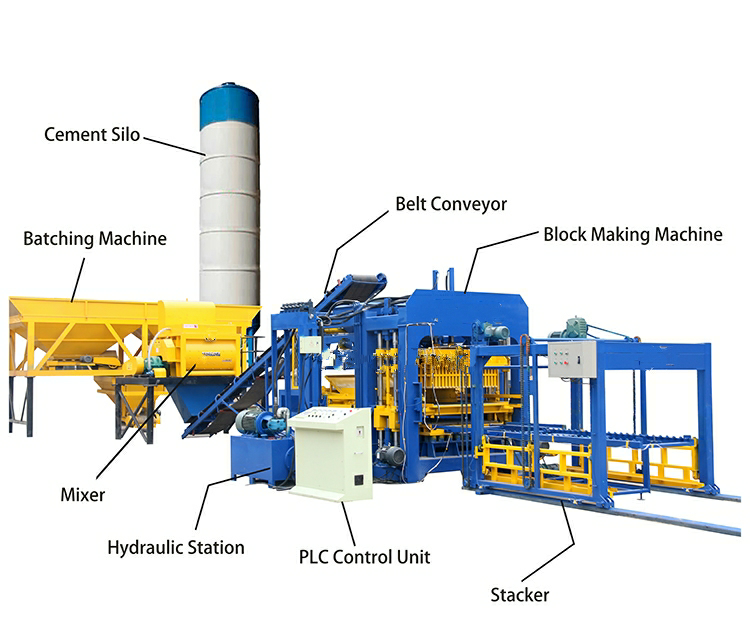

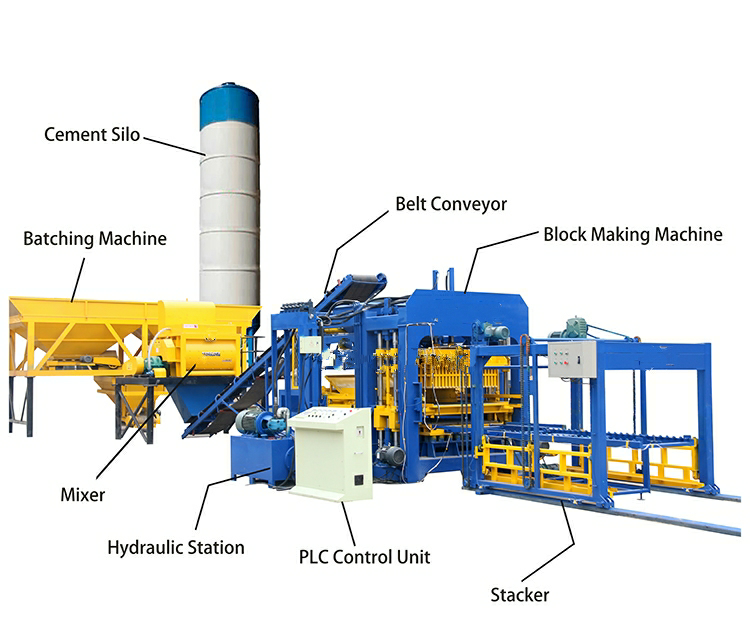

QT8-15 Automatic Concrete Hollow Block Machine is an automatic hydraulic concrete cement blocks production line. As classical big machine, it works durable and stably. This complete production line is composed of cement silo, screw conveyor machine, cement scale, batching machine, mixer, belt conveyor machine, automatic pallet feeding machine, pallet feeder, automatic stacker and block making machine. You can choose suitable supporting facilities according to your requirements.

1.The machine can produce pavement bricks, riverside bricks, blocks,interlocking blocks, square bricks, grassed bricks and so on with different moulds.

2.Low frequency in feeding material, high frequency in vibration, and platform vibrating works together with mould, so that the concrete can be fully fluidified and exhausted in two or three seconds to reach the high density.

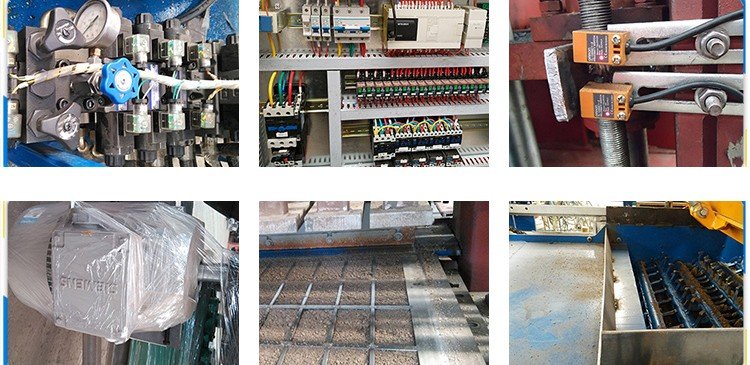

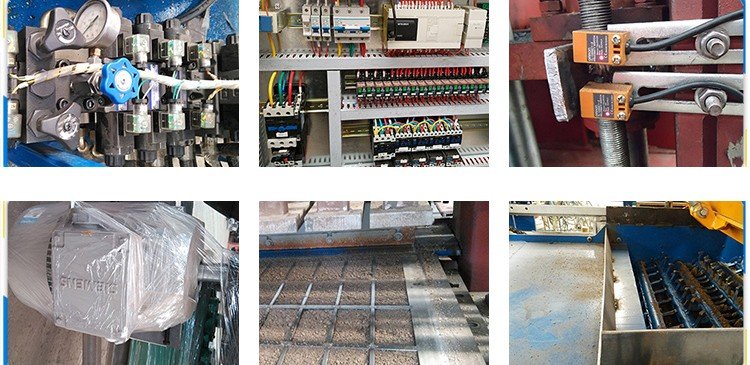

3.The advanced technique of hydraulic-controlled proportion can handle the oil press and amount of the system freely, therefore, different materials can be able to produce the high quality products.

4.All the procedures are operated by PLC. Control system also includes the advanced safe logical system and fault diagnosis system.

Features :

1. The QT 8-15 block making machine adopts multi-source vibration system, integration of PLC computer-controlled, hydraulic-driven, and electric-mechanically technology and synchronous vibration technology.

2. The control system combines digital number with monitor and sensor technology, so every movement is precise and reliable, and is very suitable for busy and complicated works. Meanwhile, the system is advanced in technology and easy to handle because it uses several hundreds of manufacturing techniques.

3. Automated self-diagnosis, the computer fault-automatic self-diagnosing system is attached to the machine, thus facilitate the elimination of any fault.

4. The block making machine can produce different kinds of concrete blocks, pavers, interlocking bricks, curbstones by exchanging mould.

Main Parameters

| Dimension of host machine | 5300*2250*2700mm | Total power | 117KW |

| Moulding area | 900*800mm | Vibration force | 80-100KN |

| Moulding period | 15-20S | Capacity | 40x15x20 22000pcs/1h |

| The size of the pallet | 960x850x25mm | Mixer model | JS750 |

| Weight of the host machine | 8.5T | General water Consumption | 5-6T/every day |

| Voltage/frequency | Adapt to local. | Worker quantity | 3 people |

Production Capacity of fully automatic brick making machine

| Size(LxWxH) | Pcs/Mould | Pcs/Hr | Pcs/10Hr | Daily capacity |

| 400X100X200 | 16 | 3,200 | 32,000 | 256m³ /per day |

| 400X150X200 | 10 | 2,000 | 20,000 | 240m³ /per day |

| 400X200X200 | 8 | 1,600 | 16,000 | 256m³ /per day |

| 400X250X200 | 6 | 1,200 | 12,000 | 240m³ /per day |

| Paver:200X100X60 | 32 | 6,400 | 64,000 | 1,280㎡/per day |

| Paver:200X163X60 | 20 | 4,000 | 40,000 | 1,,300㎡/per day |

Note:

1. Complete line of QT8-15 block making machine need 3 or 4 pcs 40HQ containers.

2. QT8-15 brick making machine also need 1200pcs GMT fiber pallet or bamboo pallets when produce blocks.

3. Raw material proportion for your reference:

a. Concrete: 10% cement, 30% sand, 60% small stones

b. 10% cement, 90% stone powder

c. 10% cement, 30% fly ash, 60% stone powder

WhatsApp us

We will contact you within 24 hours, please pay attention to the email with the suffix “Darren@iblockmachine.com”.