Today, concrete blocks are produced virtually all over the world due to their high quality and the demand for economical building materials. A variety of raw materials can be used to produce thousands of concrete units, in different sizes and shapes.

Following the information of Brother Industry, block making machines can be classified as follows:

- Mobile Brick Making Machine(Egg laying Brick Making Machine)

These models are called mobile brick making machine because they produce concrete blocks from one place to another are operated by a human operator, like egg laying, so these mobile brick making machine also called egg laying brick making machine, These models are equipped with wheels, and they are moved by electric motors, models number: 40-3A/40-3B/40-3C/6-30/10-15M

- Stationary Brick Making Machines

The stationary concrete hollow brick making machine is divided into as follows:

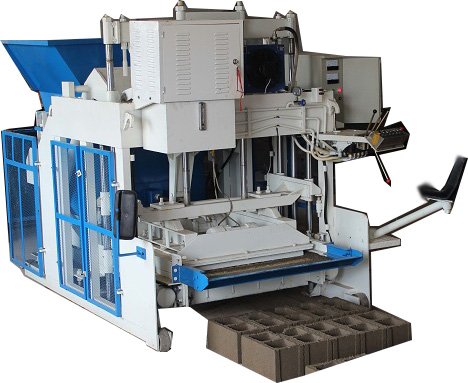

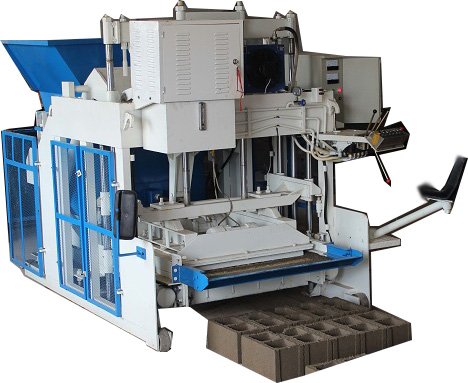

- Fully-automatic brick making machine

These machines have batch processing, automated concrete mixing and pressing systems. The transfer of the blocks is carried out by a transfer system, usually through conveyors. The productivity of these machines, depending on the block type, can range from 12.000 to 20.000 blocks in 8 hours. Human effort is minimal. These brick machines usually are the expensive machines compare with others

The different models of automatic concrete block machine are:

Automatic, not hydraulic: 4-25A

4-25 A Electric Motor Fully-automatic hydraulic brick making machine

Automatic and hydraulic:4-25D/ 4-15C /5-15/6-15 /8-15 /10-15 /12-15

Note: The Automatic and hydraulic brick machine can produce hollow-blocks, solid blocks, colour paver, curbstone

4-25A can produce hollow-blocks, solid blocks, no-colour paver.

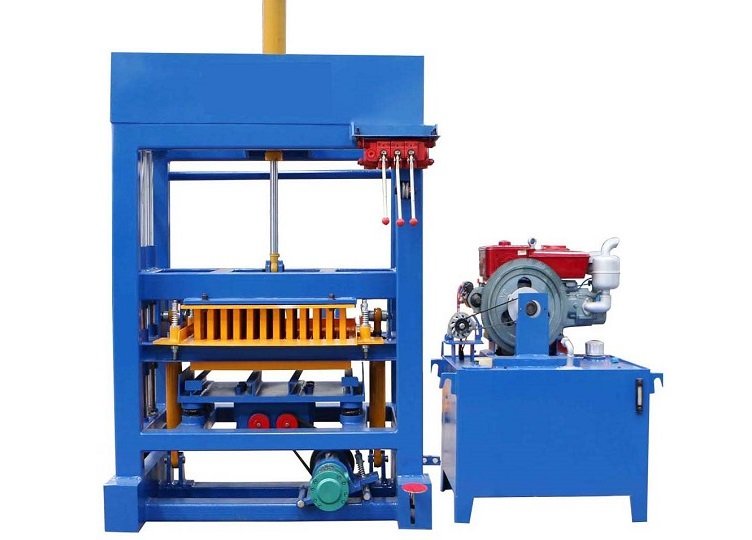

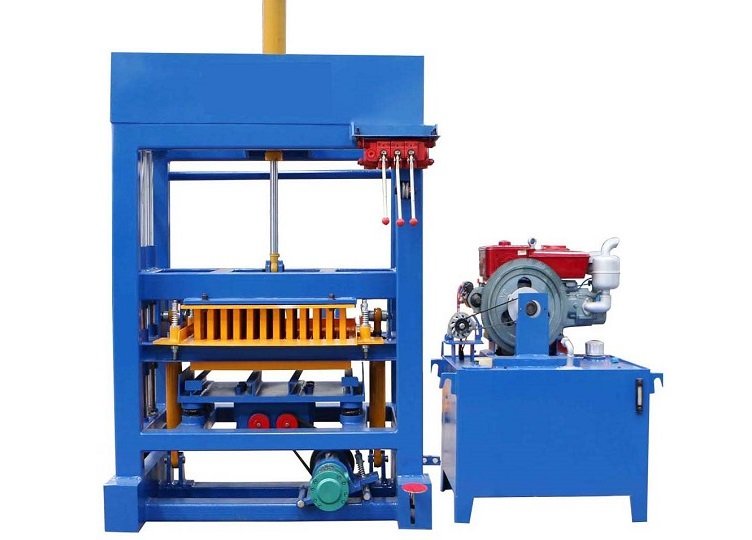

- Semi-automatic concrete block making machine (All types are no hydraulic):

These are semi-automatic because they operate with the help of a human operator.

The operator helps in switching and operates the machine to make sure that it is effective in mixing cement and sand.

The semi-automatic concrete block making machine models are:40-1/40-2/4-24/4-28

The operator also helps in the correct transfer of the formed concrete blocks to the cart and to the drying area.

Note: 40-1/40-2/4-24/4-28 can produce concrete hollow block, solid blocks and no-color paver

At the end, we must point out that the hydraulic brick making machine run through hydraulic pressure and vibration motor, so the bricks with high quality and large density, meanwhile the price is higher than no hydraulic brick machine