QT10-15 concrete hollow block molding machine is our company introduced the advanced production technology of vibration, use less power to achieve strong vibration effect, can make the raw materials can effectively fill dense flow, and the shock pressure of upper die makes the production of uniform slices the compactness, high strength, and the machine automatic upper plate automatic savings artificial fabrics, improve the economic benefit.

| Dimention | 3500 *2300 *2930mm |

|---|---|

| Pallet Size | 1300*900*30mm |

| Power | 37kw |

| Mixer model | JS750 |

| Shaping cycle | 10-15s |

| Voltage | Adjustable |

| Weight | 9.8T |

QT10-15 Fully Automatic Cement Block Making Machine is our company introduced the advanced production technology of vibration, with less power to achieve strong vibration effect, and it can also make raw materials fill and flow densely. In addition, the shock pressure of upper mold makes the production of uniform, high strength. Lastly, the machine feeds block pallets automatically, so it can improve the economic benefit largely.

Electric Power List for QT10-15 Fully Automatic Germany Cement Block Making Machine

| Item | Name | Power | Function |

| A | Batching Machine | 12KW | Measure raw material ratio such as sand, stone and other aggregate |

| B | JS750 Mixer | 38.6KW | Mix raw material (sand, stone, other aggregate, water) |

| C | Pallet Feeding Machine | 4.5KW | Feed pallet into pallet feeder box of block machine |

| D | 8m Belt Conveyor | 2.2KW | Carry mixed material from mixer to block machine |

| E | Block Machine | 52.2KW | Automatic material feeding system Automatic pallet feeding system Hydraulic station Automatic PLC control cabinet |

| F | Brick conveyor machine | 1.5KW | Carry swet blocks from block machine to stacker |

| G | Automatic Stacker | 3KW | Automatic stack fresh blocks with 4-5 pallet per layer, 2~4 rows |

| Forklift or block trolley | Carry fresh blocks from the stacker to the curing site | ||

| Total Power:114kw. Electricity is 3 phases, voltage and frequency are customized according to local requirements. | |||

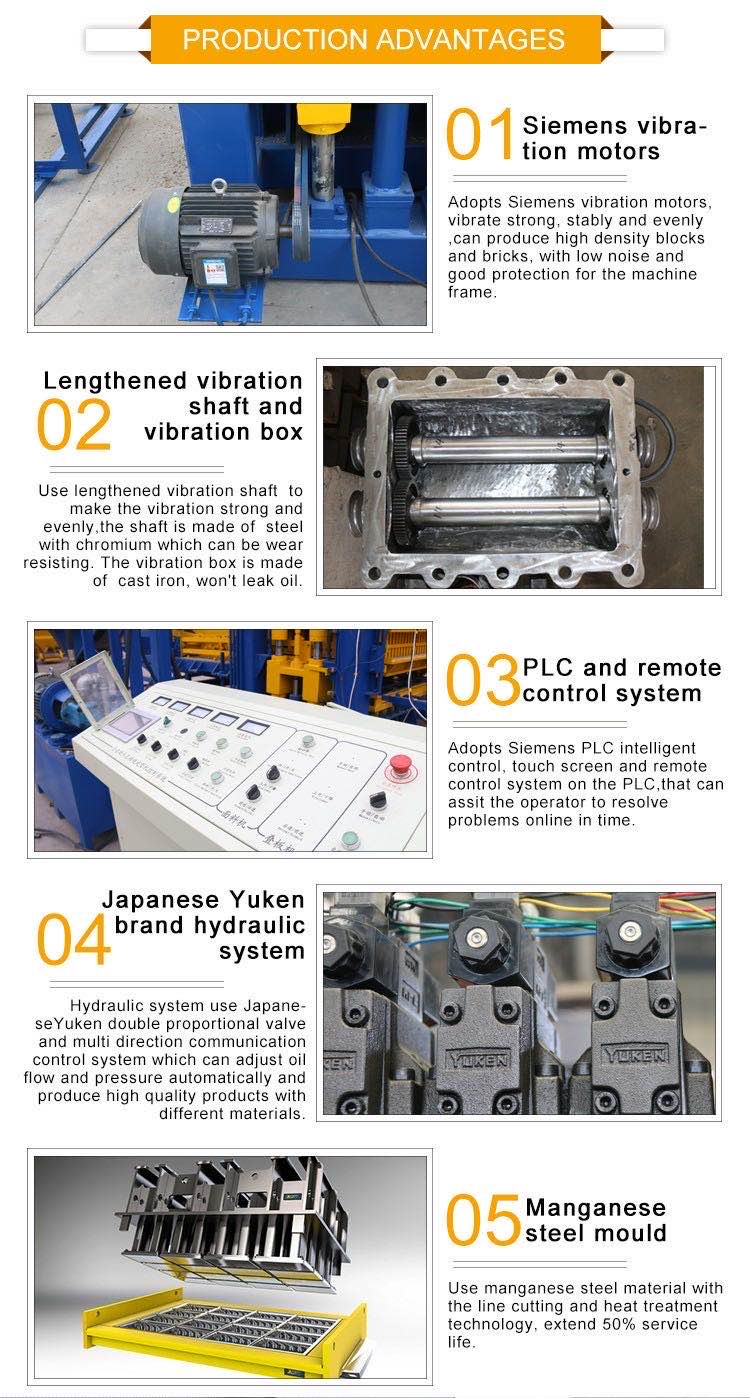

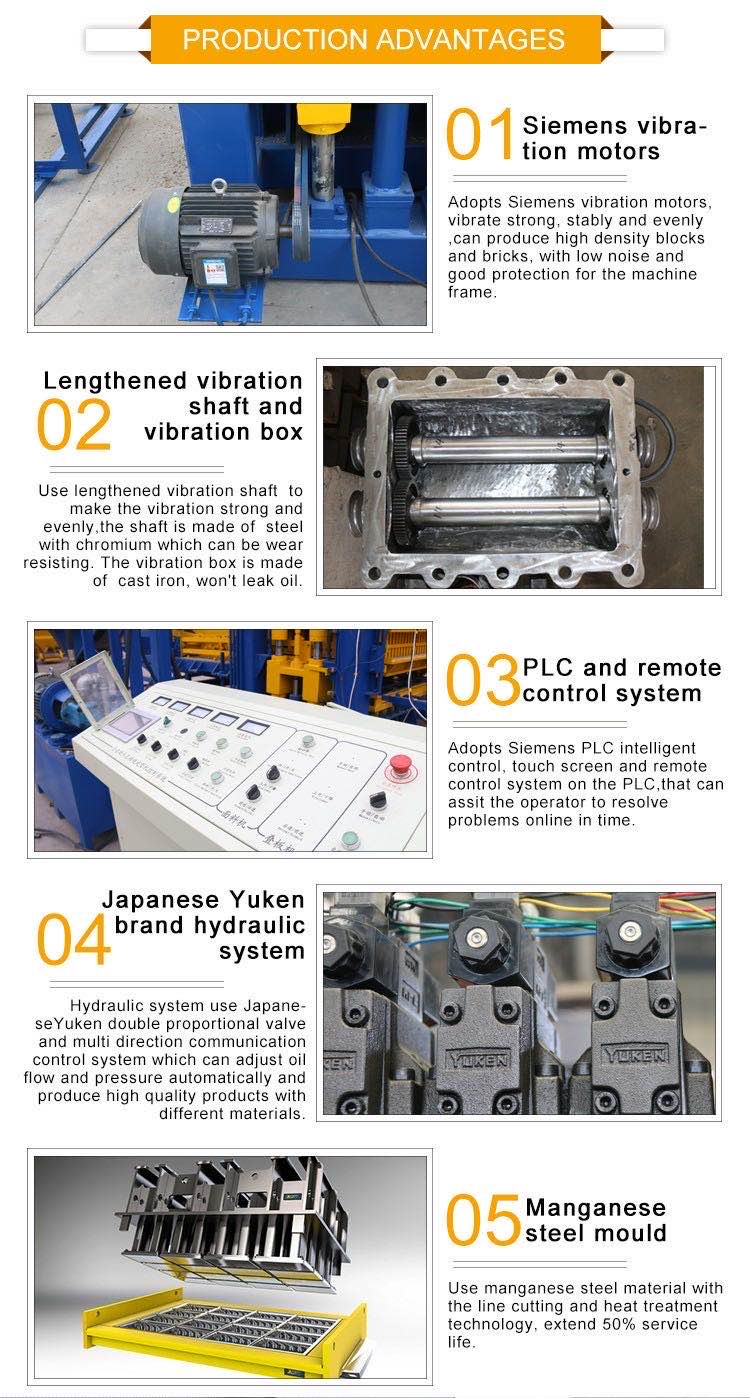

Main Features:

1: Computer PLC central control system can realize automatic production, no need workers to operate the block machine.

2: Four-bar guiding method and super-long guide bearing are adopted to ensure the precise movement of the upper mould.

3: The machine body is made of super-strength steel and special welding technology. It is strong and durable in vibration.

4: It’s quick to exchange mould to produce different specifications and shapes of pavement bricks, curbstones, hollow blocks, standard bricks, etc.

5: Electrical and hydraulic components are imported from Europe, Japan, Taiwan etc. The comprehensive performance of the equipment is stable and reliable.

6: Motors adopts the national inspection-free motor (pure copper core), and the hydraulic station adopts the special components for large hydraulic machinery.

7: Mechanical transmission, compact result, convenient maintenance, flexible operation and good reliability.

8: Strong vibration of up and down pressure makes block of high quality, especially in the production of heavy bearing high-strength blocks (strength up to 40 MPa).

9: The finished product has high strength, good compactness, precise appearance size, regular shape, no burr and angle drop.

10: Raw material could be cement, sand, stone, flyash, slag, cinder, hemp, gravel, perlite, and other industrial wastes.

Specifications for QT10-15 Fully Automatic Concrete Block Making Machine | |

| Dimension of the host machine | 5300*2350*2700 |

| Moulding area | 1250*860mm |

| Moulding cycle | 15-20s |

| Pallet size | 1300*900*30mm |

| Host machine power | 52.2kw |

| Weight | 9.8T |

| Vibration force | 100KN |

| Mixer model | JS750 |

| Voltage | 220V/240V/380V/415V/440V(adapt to local) |

| Water consumption | 10-20T/day |

| Workshop/Factory area | 260sqm / 2500~6000sqm |

Details :

QT 10-15 Concrete block machine can make many kinds of blocks only by changing moulds

| Production per mould: | 10 pcs/mould (Standard Block: 390x190x190mm) |

| 42 pcs/mould (Solid Block: 230x110x70mm) | |

| 28pcs/mould (Interlock Paver: 225×112.5x60mm) | |

| 35pcs/mould (Holland Brick:200x100x60-80mm) | |

| Cycle time: | 15-20 seconds |

| Production per day (10 working hours): | Hollow Block (400x200x200mm): 22,000pcs |

| Solid Block (230x110x70mm): 118,800pcs | |

| Interlock Paver (225×112.5x60mm): 92,400 pcs | |

| Holland Brick (200x100x60-80mm): 77,000 pcs |

WhatsApp us

We will contact you within 24 hours, please pay attention to the email with the suffix “Darren@iblockmachine.com”.